Squeaky floors create great sound effects during the Halloween season, but for builders it’s a costly reason for callbacks. Squeaky sub-floors can develop even if the subfloor installed up to code.

Sub-floors are a system consisting of floor joists/trusses supporting OSB/plywood subflooring material, to which the interior finished flooring such as hardwood, carpet or tile are attached. The joists and subfloor are commonly attached using Ring Shank nails or Screws.

After a new house has settled and the flooring lumber has dried, it tends to shrink. As flooring shrinks, it pulls away from the fastener. When you walk across this dried-out material, the nails loosen even more, causing boards to rub against each other or slide against the nails or the smooth section of screws. This motion causes creaks and squeaks. This reflects poorly on the builders and creates upset homeowners as well as upset contractors that are called back to fix the issue.

It’s possible to silence this annoyance by solidifying the connections, eliminating this movement. This can be done in a number of ways:

- adding glued shims to fill gaps (although this can backfire if the shim is too thick, making the problem worse)

- using adhesive (for minor voids)

- adding additional nails to the underside of the floor (although these can also eventually loosen)

- attach an adhesive-coated 2" x 4" or 2" x 6" to the loose joists or floorboards, tightening them with screws to establish a new, more solid connection.

- Floor Squeak Repair Kits

These call backs are not only costly, annoying, and reflect poorly on professional build quality, but are also avoidable.

First, we suggest using a high-grade subfloor material that has minimal deflection. Second, the American Plywood Association recommends the use of adhesive. When it comes to fasteners we recommend SubLoc® PRO squeak eliminating subfloor SCRAIL®.

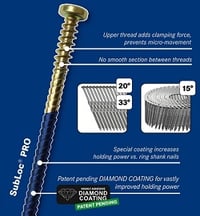

SCRAIL® SubLoc® PRO combines truly the best of both worlds offering the speed of installation a nail provides and the dynamic holding power and adjustability of a screw without the time-consuming installation time. Unlike both nails and screws, SCRAIL® SubLoc® PRO has a shank and head geometry that provides clamping force, helping pull the material tight to joist or truss AND eliminates squeaks and micromovements because of its high holding power and lack of smooth spots for materials to squeak against.

Anatomy of a SCRAIL® SubLoc® PRO

- Specially Engineered Head Design improves pull through

- Upper shank geometry grabs subfloor, provides clamping force & prevents micromovement even in the event of material shrinkage

- Electro-Galv Coating ensures no rusting even if exposed to rain

- Patented Diamond Coating increases holding power

Installation

SCRAIL® SubLoc® PRO installs easily with your existing framing nailer or with a specially designed Fasco Framing Nailer/Scrailer designed with extra features and power and optimized to drive SCRAIL® fasteners (20° & 33° strip, 15° wire, and 0° sheet plastic stocked). We recommend using a framing nailer with a flat work contact element and adjustable depth of drive to ensure fasteners not toenailed and also not over driven. Best practice installation method also calls for sequential (finger comes off of trigger after each shot) firing of fastener. This helps insure accurate placement and installation as well as insure tools are cycling properly and completely.

Always check with subfloor mfg. installation guidelines as well as local code on fastener spacing. We recommend a minimum spacing for squeak elimination of 6” O.C. on the edge and 12” O.C. spacing in the field (approx. 38 fasteners per sheet).

Benefits

- 3rd party tested to be squeak free in both glued and glue less methods when proper installation guidelines are followed

- Code approvals per CURRENT 2015 IBC & UBC requirements

- No Special Tool required

- Adjustable

- Easily identifiable

- Fast Installation

- No costly call backs

Squeak Free Guarantee

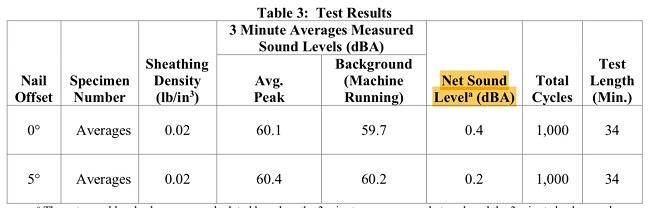

SCRAIL® SubLoc® PRO has SUPERIOR squeak free performance when installed according to guidelines with and without glue where called out. Below are 3rd party results following new guidelines to test fasteners sound rating. Sound levels less than 3dBA are proven inaudible by most human hearing. Figure 1: complete test reports available by request

Figure 1: complete test reports available by request

BECK, in business since 1904, prides itself on offering the most innovative collated fastening solutions globally. Designed to help professionals build more securely. BECK America is the North America master distributor of BECK products including SCRAIL® SubLoc® PRO.

Save TIME, save MONEY, build BETTER. Call us at 800-239-8665 or email us at sales@fascoamerica.com to learn more about the PRO PREFERRED subfloor fastener and arrange a free job site demonstration.

.svg.png)